Call us at

0203 8685 761SMART AUTOMATED STORAGE

Boost your warehouse efficiency. Optimise the storage, handling, preparation, and dispatch of all your goods.

Technological innovation for efficient warehouses

LEVELS OF AUTOMATION THAT GROW ALONG WITH YOUR BUSINESS

Automated movement

Make the most of robot efficiency to create conveyor lines that move goods through the warehouse, minimising the use of forklifts.

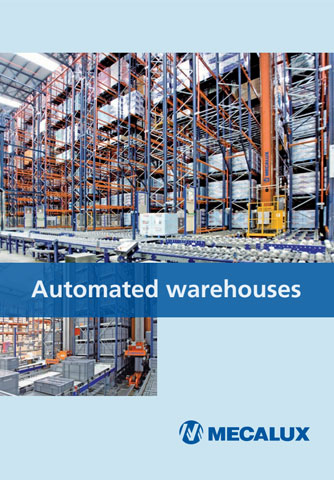

Automated warehouse

Fully automate your warehouse with stacker cranes for pallets or boxes, which insert and remove loads autonomously, or even with the automated Pallet Shuttle.

Smart warehouse

Use an advanced WMS to completely automate your entire warehouse, maximising space and achieving total efficiency.

WHY AUTOMATE YOUR WAREHOUSE?

- Total control over inventory management, eliminating errors stemming from manual management.

- Fully automated products inflows and outflows, reducing the use of forklifts.

- Maximised use of space in square metres, cubic metres, and height (up to 45 m).

- Standardisation of processes by automating repetitive tasks.

- Lower maintenance costs by eliminating impacts to the racking structures.

- Maximum high-density storage in depth when combined with the Pallet Shuttle system.

- Interconnected solutions for your supply chain through integration of a smart WMS that coordinates all warehouse movement.

THE ADDED VALUE OF MECALUX

-

Solid experience

Backed by a sound company with more than 55 years of experience, in-depth business knowledge, and a forward-thinking approach.

-

Distinctive quality

Mecalux performs all the necessary tests to know the real characteristics and behaviour of the materials used.

-

Flexibility and adaptability

Our flexible solutions adjust to each company’s needs and objectives, offering broad customisation potential.

-

Our customers endorse us

We are backed by thousands of successful deployments in small, medium-sized, and large companies from all sectors.

WHAT OUR CLIENTS SAY

WHO IS MECALUX?

As a leading manufacturer in the storage systems market, Mecalux provides warehouse automation, warehouse management software, and other storage solutions for the material handling and logistics sector.

At Mecalux, for more than 55 years, cutting-edge technology and innovative design have delivered advanced storage solutions for warehouses, including AS/RS stacker cranes, the high-density Pallet Shuttle system, a full range of pallet and box conveyors, mobile racking systems, etc.

By partnering with a high-tech company such as Mecalux, our customers gain a competitive edge with comprehensive solutions and storage designs tailored to their facilities.

LET US SHOW YOU

Learn more