Pick lists for an error-free warehouse

Picking or pick lists are used to organise the sequence for collecting products that make up customer orders in a warehouse. Generally, they consist of documents for internal use (in most cases, the customer never sees them). However, they’re extremely helpful for operators.

The preparation of pick lists and the information they contain depend in large part on the picking method followed and the warehouse equipment used. In our article, we’ll go over the information these documents should include and the advantages of having a warehouse management system capable of automatically configuring picking lists.

What should pick lists contain?

The aim of picking lists is to reflect all data in a customer’s order, indicating to the operator where the products are located in the warehouse so that he/she can collect them in the optimal order. Generally, pick lists should comprise the following:

- Pick list number

Each picking list should have a unique identification number so as to avoid duplication and facilitate the recording of a pick-list log.

- Customer information:

Although this isn’t vital for carrying out picking correctly, it sure does help to identify and check orders, especially if the various products making up the order are picked by different operators. This occurs, for example, with the batch picking method.

- Customer purchase order data

Each purchase order has a number that identifies it, in addition to other information, such as the order date, barcodes to be scanned and the assigned dispatch dock.

- Details on products to pick:

This is the most essential part of any picking list and should specify the following:

- The reference number or SKU (stock keeping unit) linked to each item.

- Product description: if the pick list document includes a brief description or picture, this will streamline the process as well as minimize picking errors. Depending on the characteristics of the stock stored, it’s crucial to specify additional data such as size or unit of measure (for example, whether the product is individual or in a box with X amount of units).

- Amount of units to pick for each SKU: if the installation is run using warehouse management software, the amount will appear on the pick list and will be updated as picking is completed.

- Information on the location of products in the installation: pick lists should be organised taking into account the location of each item in the warehouse to optimise operator movements, shorten routes and plan order prep in time for dispatch.

Pick list management with a WMS

So, how are picking lists handled with a warehouse management system? Let’s take, for example, Mecalux’s Easy WMS software: pick lists form part of the section dedicated to warehouse tasks. These functionalities organise the replenishment and procurement tasks, picking and packing operations and the preparation of orders for dispatch.

As far as picking movements are concerned, the software configuration offers a lot of flexibility. In this way, pick list preparation can be manual, semi-automatic, or completely automatic, according to the logistics parameters entered in the system. Even if the picking list is created automatically, operators can make changes to it manually, for example, skipping tasks and noting comments.

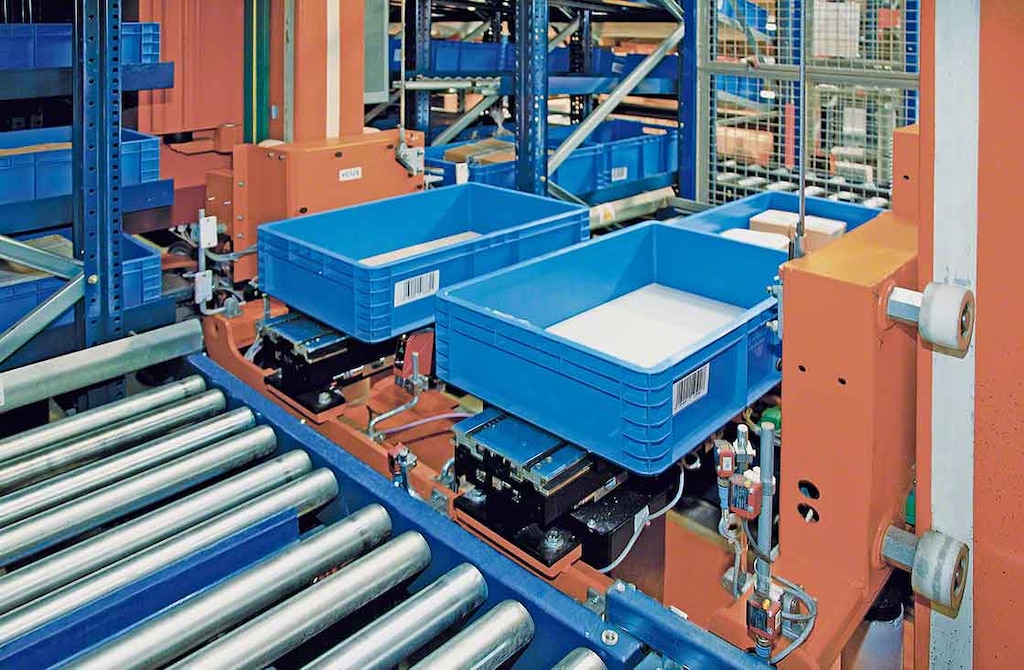

Automated pick lists are generated upon the receipt of customer purchase orders. Easy WMS extracts the information from all of them and reorganises the products to be picked by cross-referencing large amounts of data (warehouse layout, shipment priority, picking method, number of operators, etc.). Once the sequence has been decided, the software designates a container in which operators will temporarily deposit the stock in the pick list until the order is dispatched.

Easy WMS records all stock movements carried out as well as the location of the product in real time. In addition, pick lists can be printed to provide extra operator support. Picking can also be paperless, thanks to picking devices integrated with the WMS (for example, voice picking systems and radiofrequency terminals with screens).

If you’d like to see a practical demo on how a WMS can streamline and refine the preparation of pick lists, don’t hesitate to contact us: one of our experts will show you all your configuration options.