Pallet Shuttle

Semi-automatic compact system that uses an electric shuttle to load and unload the pallets inside shelves quickly and accurately.

The product

A compact storage system in which a shuttle driven by an electric motor runs on rails inside the storage channels, replacing forklifts, considerably reducing operating times and enabling items to be grouped by channels rather than complete lanes.

The Pallet Shuttle follows orders sent by an operator using a tablet with Wi-Fi connection, depositing the load in the first free placement location in the channel and compacting the pallets as much as possible. By removing the need to drive forklifts into the lanes, storage capacity is increased in terms of depth, the risk of accidents and damage to the racks is negligible, operator movements are optimised and warehouse operation is modernised and made more flexible.

It is an ideal solution for companies with a high volume of pallets per item and intensive loading and unloading activity.

Features

- Greater diversification: each channel can be used to store a different item.

- High productivity: increased flow of incoming and outgoing goods.

- Greater capacity: Storage of up to 40 m deep

- Highly cost-effective, thanks to the reduction in operating costs.

- Decreased incidents and maintenance costs.

- Many advanced functionalities can be easily controlled from the tablet.

Advantages

Technology applied at top operating speeds

Save space

- Increased number of pallets in depth: storage channels can exceed 40 m. The height limit is conditioned by the handling means used.

- The system works with minimal clearances between levels, which allows for high-density storage.

- Through the use of sensors the shuttles can position loads intelligently, eliminating empty spaces in the storage lanes. As such, the effective capacity of the warehouse (which takes into account flows of goods in and out of the warehouse) reflects its physical capacity.

Save time

- Loading and unloading times are reduced, since the operator does not need to work inside the lanes.

- Movement speed of the shuttle of 90 m/min when empty, or 45 m/min when loaded.

- Load lifting cycle of just 2 seconds.

- On being given a single command, the shuttle can fill or empty a whole lane.

Increased productivity

- Increased flow of goods in and out of the warehouse.

- Unlike conventional drive-in systems, references can be grouped by channel, rather than requiring a full lane, which allows for greater diversification.

- Optimisation of operator movements. Product-to-person system: this is the load that moves to the operator.

- While the Pallet Shuttle carries out a command, the operator can collect another pallet, thus achieving continuous movement.

- Depending on temperature and load conditions, the shuttle has an operational range of up to 10 hours, working at full capacity.

- The lithium batteries are easily accessible and have fast connections that eliminate the need for cables, so that they can be changed quickly without interrupting the operation cycle.

- Elimination of errors.

- The system is easy to use and easy to maintain.

- A single tablet can control up to 18 shuttles.

- Inventory function: The shuttle can take stock of the number of pallets stored in a channel.

Save money

The result of the benefits mentioned previously, together with the consumption of energy, is a reduction in costs, making Pallet Shuttle one of the most cost-effective compact storage systems.

Versatility

- The shuttle has built-in sensors that enable different types of pallets to be detected and handled.

- The Pallet Shuttle models 1012 and 1212 are able to work with pallets of different widths and sizes. The 1012 model can be used to handle Euro-pallets of 800 or 1,000 mm in width. The 1212 model can be used to handle Euro-pallets of 800, 1,000 or 1,200 mm in width.

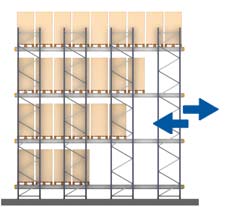

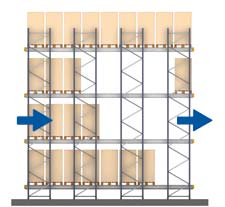

- All shuttles can operate in LIFO or FIFO mode. The operator uses the tablet to select the mode he wishes to work with.

- The shuttle platform is designed to carry pallets with a buckling limit of up to 25 mm.

- Any type of handling equipment can be used to carry the shuttle.

- Up to 1,500 kg per pallet can be handled.

- It is possible to install Mecalux's Easy WMS Warehouse Management Software on the tablet.

- The system is scalable. Over time, the number of shuttles can be increased easily as the need to increase productivity arises.

Safety

- Thanks to the way that the structure is built, and given that forklifts do not need to drive into the lanes, the risk of accidents is practically non-existent, and the metallic racks are not damaged, meaning maintenance is kept to a minimum.

- There is a user management feature that prevents unauthorised personnel from using the shuttles.

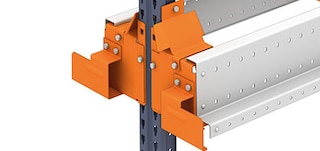

- Both the racking and the shuttles have built-in safety features specifically designed to ensure the correct operation of the Pallet Shuttle system: rail end stops, pallet centralisers, position sensors, etc.

Mecalux Guarantee

Mecalux designs and manufactures all the component parts of the Pallet Shuttle compact storage system, including the specific racking structure to ensure optimal movement of the shuttles, and the shuttles themselves.

This guarantees perfect operation and a perfect fit for all the different elements of the system, as well as their quality and compliance with the safety regulations in force in each country.

Thanks to the resources invested in R&D&I, Mecalux's Pallet Shuttle includes the latest technological innovations, offering optimal performance at a very competitive price. It has innovative features, including remote control via tablet, the positioning camera and the safety scanner. Additionally it is one of the fastest systems on the market and can be adapted to the specific needs of any warehouse, making it even more efficient.

Mecalux provides a warranty of five years for the Pallet Shuttle racking structure, of one year for the operation of the shuttle, and of six months for the operation of the batteries.

About

A way of quickly and regularly transporting pallets back and forth

According to the dictionary definition, a shuttle is a vehicle that travels to and fro between fixed points at frequent intervals. Mecalux's Pallet Shuttle fits this description perfectly, with the route in this case running from the rack's P&D station to the first available space in the storage channel (or the opposite way, if unloading).

At one point, the evolution of compact storage systems raised the following question: Why not make it a motorised shuttle, not a forklift, that enters the storage channel to handle pallets, increasing loading and unloading speeds and optimising the effective capacity of the warehouse?.

The smart answer was Pallet Shuttle: the racking structure is adapted so a shuttle with an electric motor can move along the inside of storage lanes on a track, following the commands given by the operator using a Wi-Fi tablet.

The forklift leaves the load on the track, and the Pallet Shuttle picks it up and moves it independently, storing it in its placement location, all the while keeping the pallets as compact as possible. By removing the need to drive forklifts into the lanes, handling times are reduced, storage capacity is increased in terms of depth, the risk of accidents and damage to the metal shelves is negligible, operator movements are optimised and warehouse operation is modernised.

This is how the Pallet Shuttle system offers a compact storage solution that reduces operating costs and improves performance in the supply chain. Making progress the smart way.

In Action

Compact semi-automated warehouse with Pallet Shuttle

In semi-automated installations, operators only need to drive the forklifts that carry the pallets and initiate the motorised shuttle's activity. The movement of the shuttles inside the racks is automated.

Components

In addition to the control tablet that communicates orders to the shuttle via Wi-Fi, the system consists of two basic components:

FIFO / LIFO

Load management systems

The semi-automated system allows for two types of operation:

Applications

Automation at everyone's fingertips

In general, the Pallet Shuttle noticeably increases warehouse productivity when working with incoming and outgoing goods with a large number of pallets per discrete item.

As such, it is the perfect option for:

Downloads

Catalogue

DownloadAsk an expert