Citres: earthquake-proof racking and agile goods management

The direct access to the pallet racks facilitates the management of 200 incoming and outgoing pallets a day

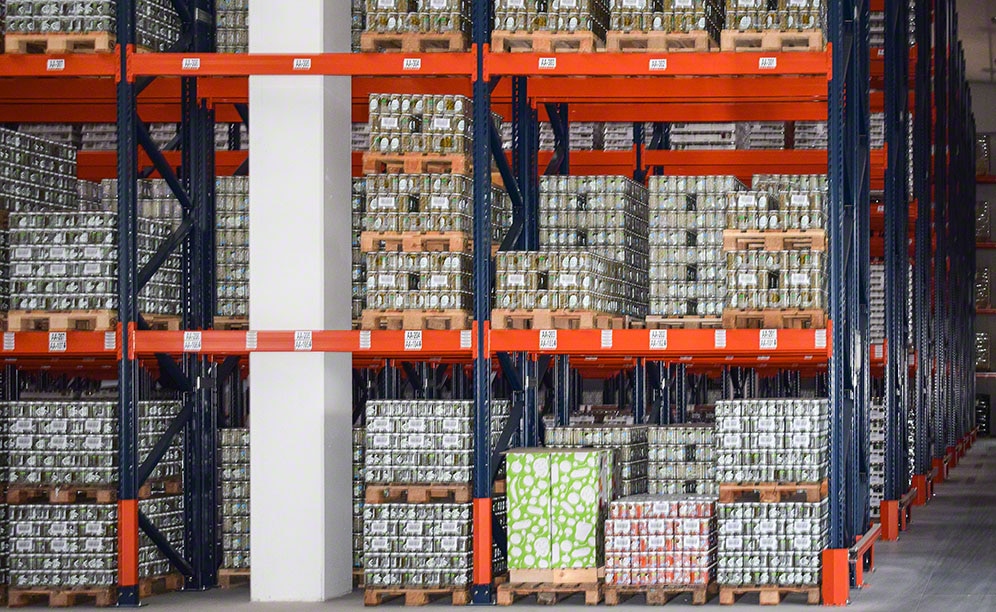

Citres, an Italian producer and exporter of preserves, has installed seismic racking from Mecalux in its warehouse in Bovolone, Italy, with capacity for 3,200 pallets. This facility stands out for its secure storage of food and for its agile, efficient operations that guarantee speedy order picking and dispatch.

Citres: preserves around the world

Founded in 1958 in Verona, Citres is a renowned preserves company that sells all kinds of products in oil as well as pickled goods, from anchovies to olives and capers. All its food is made in line with sustainable practices that foster the protection of the environment.

In a surface area spanning 30,000 m², this family-run business has three warehouses with a storage capacity of 10,000 pallets and three production lines that bottle 15,000 jars/hour. During peak season, Citres can dispatch up to 600,000 jars of preserves a day.

A total of 40% of Citres production is exported to northern Europe, the US, and Australia, while the remaining 60% is distributed in the Italian market.

Versatility and security

Citres needed a solution that, in addition to maximising storage capacity, would provide direct access to facilitate storage and order picking tasks. Andrea Bellè, Logistics and Distribution Manager at Citres, says: “Our main need was to have more space to store all our SKUs.”

Mecalux has installed two single-deep pallet racking units and eight double-deep ones. With five levels, they stand 9 m tall and can store 3,204 pallets with a maximum unit weight of up to 1,100 kg.

Safety is a priority for Citres, in both the production storage processes. The company is headquartered in the Verona region, one of seismic activity, so the racks had to be sufficiently strong and secure. In this regard, the racking was calculated taking into account the indications of Italian standard NTC 2008 and European standard UEN 16681. This means that they were specially reinforced to support any possible ground motion that could occur in the region.

These types of racks were also chosen because they are specifically designed to facilitate goods handling.

Citres works with 540 SKUs, and it receives nearly 200 pallets every day. Having direct access to the products expedites all operations in the centre. That is, the operators use reach trucks to insert and remove the pallets from their locations very nimbly.

Product traceability is essential for Citres, since the company works with food that must undergo strict quality control. For this reason, the operators, equipped with RF scanners, follow instructions from the management system when storing and dispatching the goods.

The pallet racks have also helped to improve stock control and to optimise organisation in the warehouse. And all of this results in increased throughput in the facility as well as better service.

Logistics competitiveness

With this warehouse, logistics operations at Citres are highly productive and efficient. The pallet racking has enabled the businesses to maximise its storage capacity, speed up operations and improve stock control.

Bellè says: “The company is growing at a dizzying pace. Some of Citres’ future objectives will include speeding up order picking, reducing errors and avoiding stockouts.”

Mecalux pallet racks have enabled us to manage locations in our warehouse with high accuracy.

Advantages for Citres

- Maximum storage capacity: in total, the pallet racks offer storage capacity for over 3,000 pallets.

- Increased productivity: the direct access to the racks makes it possible to move close to 200 pallets into and out of the warehouse every day.

- Seismic resistance: the pallet racks are calculated and specifically reinforced to withstand any ground movement.

| Pallet racking | |

|---|---|

| Storage capacity: | 3,204 pallets |

| Pallet size: | 800 x 1,200 mm |

| Max. pallet weight: | 1,100 kg |

| Racking height: | 9 m |

Gallery

Citres' pallet racking can store over 3,000 pallets

Ask an expert