Toy manufacturer Créations Dani modernises its warehouse in France

The warehouse of the toy manufacturer Créations Dani runs the Mecalux Easy WMS

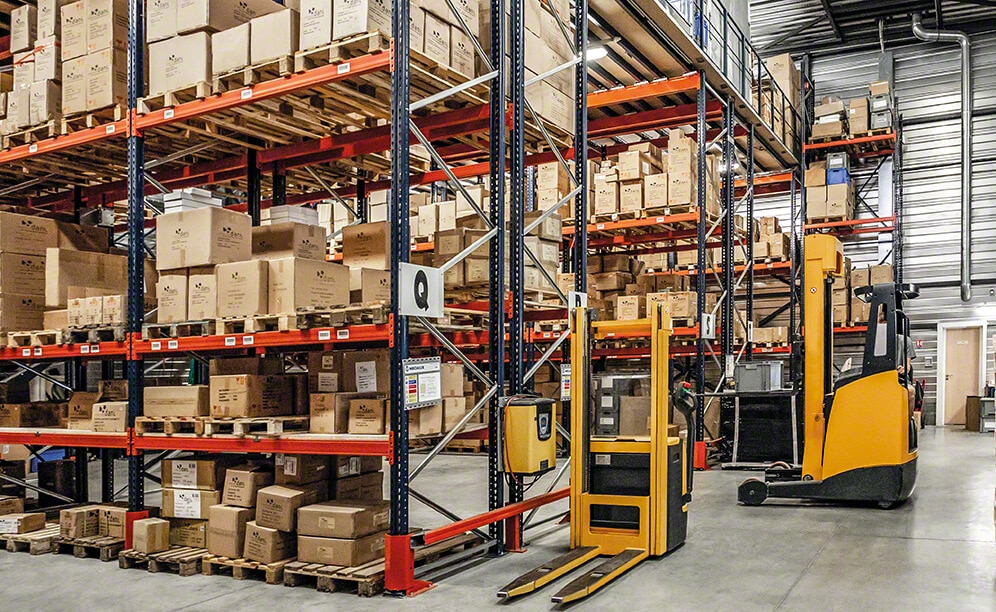

Créations Dani is a French souvenir company that keeps updating its logistics to meet new market demands. Its warehouse in Saint-Ferréol (a town close to the Swiss border) has been expanded three times with the help of Mecalux, all to accommodate a larger number of items. Recently, it rolled out theEasy WMS management system to raised the productivity of every operation.

Putting the “W” in warehouse

Founded in 1979, Créations Dani manufactures and sells stuffed animals, toys and souvenirs. In 2011, it opened a 700 m2 warehouse in Saint-Ferréol (France) from which it supplies the 800 points of sale it owns and operates in France, Italy, Switzerland and Austria.

Créations Dani has always relied on Mecalux’s collaboration when it comes to finding a storage solution that gives the best possible capacity and, of course, speeds up picking. As a result of the advice provided, the warehouse has been extended on numerous occasions.

At first, the warehouse comprised a 1,000 unit load capacity in pallet racks and a mezzanine with shelving for picking on the upper floor. Lately, the centre expanded with Movirack mobile pallet racks to hold an additional 1,120 pallets.

According to Damien Cornu, co-director of Créations Dani, “we worked using pen and paper. But, if we wanted to enhance our growth and increase productivity, we had to implement more modern solutions like a warehouse management system.”.

Mecalux proposed the deployment of Easy WMS, the WMS capable of adjusting to this warehouse’s operations and special features. All operations are managed automatically through this system: inputs, outputs, storage locations, inventory, order preparation, etc. “We found the proposal both affordable and good value for money,” Damien Cornu stressed.

The commissioning phase is one issue that most concerns companies who want to rework their logistics with a WMS. The co-director of the company recognised that “our activity was never disrupted and the software’s roll out went smoothly; the software works without a hitch.”

In fact, Mecalux’s Easy WMS has completely reinvented the logistics of Créations Dani. Damien Cornu named some advantages: “It has helped us embrace a new way of warehouse organisation. We’re now more efficient and better equipped to manage our storage space. We often wonder how we managed everything without Easy WMS. And nothing in the world would make us switch back to our previous system.”

Easy WMS is a very intuitive and easy-to-use tool. According to Damien Cornu, “when new recruits join the workforce, they only need about two hours of training.”

Warehouse features

Créations Dani manages a catalogue with more than 5,000 items, as well as 3,384 pallets and containers. More than being a necessity, order is a priority to avoid even the slightest possible error while preparing orders.

Mecalux has installed three storage systems with different applications to organise all these items:

Pallet racks

This solution is designed to store a large number of pallets with many SKUs. Its structure easily adapts to any load, weight and volume variables such as, toys and other fast-moving products in bulky boxes.

The racks offer direct access to the products, which makes it extremely dynamic when managing goods and preparing orders.

Mezzanine with shelving for picking

Some 5.5 m high racks were installed, on which rests a raised aisleway and shelving for picking.. This solution has doubled warehousing space providing increased capacity.

Shelving for picking allocated to small products (key rings, magnets or pens) also gives much needed direct access to the goods. This characteristic is essential to speed up the work of storage and preparation of orders.

Movirack mobile pallet racks

The racks are placed on mobile bases that move laterally and autonomously. This system compacts space by eliminating how many aisles are required, without losing direct access to pallets.

The operators select the right aisle to work in using a remote control. The shelves separate in a cascade like manner, leaving a space open between the chosen shelves for loading and unloading of the goods.

These racks are used to store Créations Dani’s medium and low rotation products, such as oversized products.

Intelligent management with Easy WMS

“Easy WMS struck a chord with us as the best WMS around because it has met our requirements and simplified all processes,” Damien Cornu said. The system controls, coordinates, and manages all warehouse movements. The WMS intervenes and multiplies throughput in all areas: reception, storage and dispatch of orders.

Damien Cornu - Co-director at Créations Dani

“Easy WMS has completely revolutionised the way we work. Since 2010, Créations Dani has recorded an annual growth of around 10%. Without a doubt, Easy WMS is an indisputable part of this increased turnover.”

Receipt of goods

The reception area is especially important because that is where the products are received. Additionally, pallets remain standby until they are assigned an in-house location. Products must be identified by a barcode.

Even though most of them already have one because the supplier has placed it, some items do not. In these cases, the WMS is programmed to create a label that is printed and stuck to the pallet.

Product storage

Easy WMS organizes merchandise in locations based on predefined rules and strategies (product dimensions, demand level, production date, etc.). “The FIFO (first in, first out) principle is followed, i.e. the first pallet to enter is guaranteed to be the first one out,” Damien Cornu said.

Products with similar characteristics (e.g. key rings) are deposited in the same area. Thanks to this organisational approach, operators know which warehouse area to go to when preparing an order.

Knowing the stock’s status and where each product is found has brought great results for the company. “Easy WMS has given us all the advantages of a good WMS: traceability, perpetual inventory, high performance and error reduction,” Créations Dani co-director pointed out. By monitoring all products, the company can tell whether it has enough merchandise to be able to process orders placed by customers.

Order preparation

The WMS has contributed to higher picking accuracy and improved picking times. And to top it off, “we’ve doubled the number of orders we prepare daily,” Damien Cornu said excitedly

The system has automatically designed a route for each operator to optimise their movements when picking. The WMS assigns them a warehouse area to work in and tells them which products to pick, in what amount and where to find them.

Communication comes number one between the WMS and the operators. Operators use RF devices to receive orders and confirm that the orders have been fulfilled. The advantage of this system lies in the ability to concentrate on task execution, without having to stop and question a decision.

Improved performance

Mecalux’s Easy WMS has maximised the outlook of Créations Dani’s distribution centre and optimised storage capacity and order picking. To align warehouse operations with company requirements, Easy WMS seamlessly and bidirectionally communicates with Créations Dani’s Divalto ERP. The ERP informs the WMS of all incoming orders to be received, as well as the orders to be prepared. Being integrated with the ERP, the WMS generates real data about the stock’s status, which makes planning supplier purchases possible based on available stocks and sales forecasts.

Advantages for Créations Dani

- Faster order prep: the warehouse management system has doubled how many orders are prepared on a daily basis thanks to well-organised merchandise and a pro-optimised route design for better operator movements through the warehouse.

- Merchandise control: all items are identified from the moment they arrive at the warehouse, meaning that the company has real-time knowledge of the status of the 5,000 SKUs it has stored.

| Créations Dani warehouse: Pallet racks | |

|---|---|

| Storage capacity: | 2,264 pallets |

| Pallet size: | 800 x 1,200 mm |

| Max. pallet weight: | 700 kg |

| Racking height: | 6.5 m |

Gallery

Créations Dani’s warehouse for toys in France

Ask an expert