Traceability and control of Maison François Cholat's farming products

The solutions company for farmers and ranchers has implemented Easy WMS in its warehouse in France

Digitalisation has brought considerable benefits to Maison François Cholat: total traceability of its 1,800 SKUs, reduced logistics costs, increased productivity and streamlined preparation and dispatch of its 100 daily orders. The firm has implemented Easy WMS, the warehouse management system by Mecalux, in its 2,500 m2 distribution centre in Saint-Quentin-Fallavier, France. With this, it aims to boost its supply chain and provide improved service.

Innovation and modernity

Maison François Cholat is headquartered between Morestel and La Thuile in eastern France where, in 1877, the Cholat family bought a mill dating back to 1461.

Innovation has always formed part of Maison François Cholat’s DNA. Passed on from generation to generation, the concept of transformation has always been present in this company. It is what has enabled it to endure and adapt to market demands.

Initially, milling was the firm’s main activity. However, over the years, it has expanded and diversified its business. Currently, it is devoted to three other complementary undertakings: harvesting and collecting cereals, as well as selling seeds, animal feed, plant-protection and other products and tools for farmers, such as wooden stakes, wire mesh and fences.

Maison François Cholat has 31 installations in total in the same region, including the mill, three animal feed factories, some twenty silos that store corn grains, a distribution centre and multiple sales outlets.

Logistics first and foremost

In 2014, the company started up a 2,500 m2 distribution centre in the town of Saint-Quentin-Fallavier to group together as many goods as possible (mainly products for farmers) under the same roof. “Now, all the orders are centralised and shipped from this facility,” notes Morgane Cholat, Logistics Manager at Maison François Cholat.

The centre is comprised of a silo with a capacity for 15,000 tonnes of grain, two dryers that reduce the humidity of the harvested grain and a warehouse that stores 1,800 SKUs of items used to supply hundreds of farmers, grain producers and ranchers located in the south-east of France.

According to Morgane Cholat, “logistics has become increasingly important for our business. It is not just a matter of selling products and having a carrier deliver them to the customers; it is a decisive factor for achieving greater profitability. Because of this, we were convinced that we needed to renovate, improve and refine our supply chain.”

The company set out to install a warehouse management system (WMS) with two very specific objectives:

Modernise the business

Only two employees work in the installation. Previously, they were the only ones who knew the exact location of the 1,800 different items. Both workers had become essential, as the absence of one of them led to service delays.

The desire to update its flows drove the firm to implement a new WMS. As explained by François Maxence Cholat, Harvest Department Manager at Maison François Cholat, “our warehouse in Saint-Quentin-Fallavier is located in the heart of France’s most important area of logistics activity. All the warehouses there are managed by means of sophisticated software solutions. We did not want to get left behind, and we wanted our employees to have the most attractive and useful working tools (nothing to do with obsolete methods such as pencil and paper).”

Attain complete traceability

In France, the sale and storage of plant-protection products are two highly regulated activities. Since 2016, total traceability of these types of goods has been mandatory. Traceability involves all stakeholders in the sector, from manufacturers to sales outlets. Consequently, Maison François Cholat must carry out accurate monitoring of the goods, track their path and know ahead of time which route they will take.

Morgane Cholat stresses, “The company has always been concerned with traceability. Even before current legislation was implemented, we were pioneers in tracking plant-protection products. We needed a WMS that would enable us to find a customer to whom a specific item was sold and that would record relevant information, such as the production date or batch number. This way, if necessary, we would be able to recall a product from the market very easily.”

Nowadays, the firm only monitors plant-protection products and organic seeds. Nevertheless, it plans on establishing complete traceability for other items, such as seeds and processed cereals. “This is a real demand from the sector, from farmers to consumers, and we want to be prepared to anticipate future traceability requirements,” affirms Morgane Cholat.

Warehouse control and efficiency

François Maxence and Morgane Cholat note, “After comparing various WMSs, we chose Easy WMS by Mecalux because we feel that it adjusts perfectly to our specifications. When making our decision, we also valued the seriousness and professionalism of Mecalux’s technical team, which convinced us by effectively answering all our questions.”

Easy WMS is able to monitor the products rigorously, thanks to the combination of three elements:

- Goods identification. Pallets arriving at the warehouse are identified via a barcode or QR code.

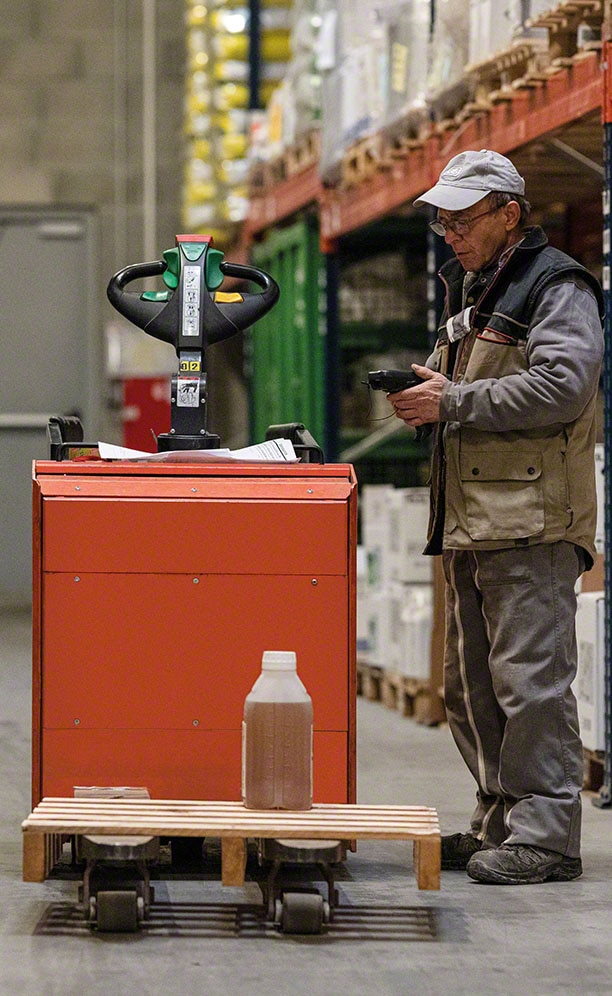

- Pallets arriving at the warehouse are identified via a barcode or QR code. Operators use radiofrequency terminals with barcode readers to identify the items, enter them into the system and know all their details. In reality, this device acts as a bridge between the physical and digital worlds.

- Data processing. The WMS compiles and stores the data pertaining to each item. This software incorporates rules and algorithms to assign the products a location according to their characteristics, batch, turnover, etc.

Optimal goods organisation leads to better management of stock, resources and flows. Order is essential in Maison François Cholat’s installation — without it, it would be impossible to move 1,800 SKUs without error. To that end, smooth communication between Easy WMS and the company’s ERP is indispensable; this maximises operations and ensures that they meet the firm’s business needs.

An average of 20 pallets arrive every day. They are sent from various suppliers and identified by operators using radiofrequency terminals.

Immediately afterwards, Easy WMS decides where each item should be placed and instructs the operators to deposit the goods in the appropriate locations. “The logic followed by the WMS to store the goods is based on the production date and batch,” explains Morgane Cholat. As the FIFO (first in, first out) principle is used, the merchandise is stored as per its production date. Everything is organised in such a way that the items that are manufactured before are dispatched first, unless the ERP requests a specific batch for an order.

In addition to organising the products, Easy WMS intervenes in all warehouse processes and supervises operators’ work so that they can prepare and distribute as many orders as possible throughout the day. The system can design a route for storage and picking tasks that optimises operator travel, thereby reducing movements.

To prepare the orders, operators move around the warehouse, picking the products that comprise each package directly from the shelves. They follow an order grouping method, which consists of picking multiple SKUs for several orders on the same run. Every day, operators complete approximately 90 orders, which are shipped directly to professional customers or to sales outlets. There, farmers purchase the goods they need to work in the fields.

The operators use radiofrequency terminals to know which products to store and which to pick. By means of these devices, the workers communicate in real time with the WMS to receive orders and confirm that they have been fulfilled. This system helps them to concentrate on their work; consequently, this elevates throughput and practically eliminates errors.

“We are pleasantly surprised by how user-friendly and intuitive Easy WMS is. New employees learn to use this technology really quickly,” highlights Morgane Cholat.

François Maxence Cholat y Morgane Cholat - Managers of the Harvest and Logistics Departments, respectively, at Maison François Cholat

“We are satisfied with Easy WMS by Mecalux and would recommend it to other companies. It is a system that meets all our requirements: traceability and agility in storage and order prep tasks. Time saved on operations is especially noticeable in picking, since the employees find the products they need very quickly and without making mistakes.”

A digital future

Easy WMS has transformed Maison François Cholat’s logistics systems and contributed towards increasing productivity, streamlining operators’ work and ensuring goods traceability. The company has gone from using pencil and paper to organise 1,800 SKUs to doing so in a completely automated and error-free way.

“We are planning to open more warehouses, and if we have learned anything from this first experience with Mecalux, it is that our employees need to rely on a tool as efficient as Easy WMS. We would implement Mecalux’s WMS in another installation without a doubt,” affirms François Maxence Cholat.

Advantages for Maison François Cholat

- Goods traceability: Maison François Cholat identifies the 1,800 SKUs from the moment they arrive at the warehouse and knows their exact location at all times.

- A modern supply chain: management is no longer carried out with pencil and paper. Now, a single system knows the status of the inventory and helps to provide improved customer service.

- Streamlined and efficient operations: operators follow instructions from Easy WMS on how to carry out storage and order prep tasks. This provides increased safety and prevents errors.

| Maison François Cholat | |

|---|---|

| Warehouse surface: | 2,500 m² |

| No. of SKUs stored: | 1,800 |

Gallery

Maison François Cholat's operators use radiofrequency terminals

Ask an expert