The Steris automated warehouse is allocated to the sterilisation of products

Products from the healthcare and pharmaceutical sector are sterilised in the Steris warehouse

Sterilisation is a process that eliminates the microbial load of a product, leaving it free from all types of microorganism. Steris, a company specialising in medical, pharmaceutical and cosmetic sterilisation has automated one of its new distribution centres in the town of Chusclan (France), with the aim of improving its service quality.

Present in over one hundred countries

Founded as Innovative Medical Technologies in Ohio in 1985, the company was renamed Steris in 1987 and now has offices in China, France, Germany, the Netherlands, Switzerland and the United Kingdom.

In France, Steris had only one distribution centre, located in Marseille. However, in the words of Kévin Chautemps, the company’s maintenance manager, “we had insufficient storage capacity and could not increase our annual production.”

That is why a second warehouse has recently been opened in Chusclan. It processes orders from pharmaceutical, cosmetics, and health companies.

Automation: no downside

Steris understood that to offer better customer service, it had to update all its production processes, including logistics. To this end, it opted to simplify and automate the operations at its centres.

Automation has provided Steris with many benefits, such as increased productivity, reduced operating costs and perfect control of the goods.

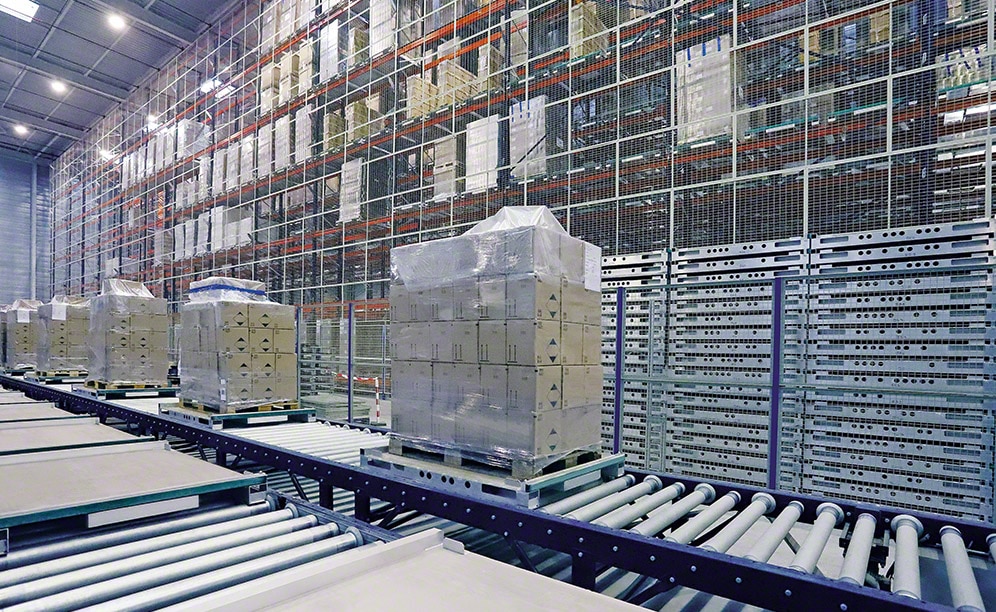

Mecalux equipped the 4,140 m2 distribution centre in Chusclan with an automated warehouse of over 1.000 pallets. “With this installation, we have doubled the original storage capacity of the Marseille warehouse so we can meet our growth prospects and fulfil customer demand,” explains Kévin Chautemps.

The warehouse has two floors (the upper one for entries and the lower one for exits) and is composed of two 54 m aisles with single-deep racks; it is 15.5 m high on both sides. Space has been reserved for an additional aisle in the future.

Warehouse operations do not require manual processes. “We knew very well that we needed an automated solution to respond as quickly as possible to our customers,” stated Steris’ Maintenance Manager.

Every day, 180 pallets are received from customers all over the world (mainly from France, Italy, Spain and Germany). Immediately afterwards, the conveyors move them to the corresponding aisle and a stacker crane deposits them in their location. Automating storage tasks and implementing Easy WMS, Mecalux’s warehouse management system, have made exhaustive and real-time control of goods simpler and easier. The WMS distributes the pallets to the locations according to their characteristics and rotation. It also organises reception and delivery of the pallets to the sterilisation area and their subsequent dispatch.

Kévin Chautemps - Steris Maintenance Manager

“Steris has a very good relationship with Mecalux. From the outset, Mecalux understood the importance we attach to safety in the goods sterilisation process. Furthermore, the automated solution installed has allowed us to double our initial storage capacity.”

Ionising radiation

Steris’ centre is much more than just a warehouse where goods are inserted, stored, managed and shipped; they are also sterilised there. On the lower floor of the warehouse, a conveyor circuit transfers the pallets to an area where this process is carried out.

To ensure that micro-organisms are completely eliminated from the products, this area is restricted and is not accessible to operators. According to Kévin Chautemps, “the fully automated installation supplied by Mecalux has enabled us to guarantee greater effectiveness in sterilising products”.

Advantages for Steris

- Goods control: the automated warehouse and the WMS of Mecalux have promoted real-time product supervision, which is essential when dealing with sterile products for use in hospitals or pharmacies.

- Maximum possible safety: automation means operators do not handle the goods, so the sterilisation process can be carried out with full guarantees and without errors.

- Swift operations: the stacker cranes and conveyors carry the goods to their corresponding location very quickly and operate 24-hours a day.

| Automated warehouse of Steris | |

|---|---|

| Storage capacity: | 1,000 pallets |

| Pallet size: | 1,140 x 1,360 x 2,100 mm |

| Max. pallet weight: | 1,200 kg |

| Racking height: | 15.5 m |

| Racking length: | 54 m |

| No. of stacker cranes: | 2 |

Gallery

Product sterilisation takes place in the Steris warehouse

Ask an expert