Mecalux racking for the clothing and fashion accessory e-commerce TopTex

TopTex's picking shelves make it easy to prepare orders

Mecalux has participated in the renovation of the two warehouses owned by the e-commerce company TopTex in Belgium and France, where it manages more than 34,000 pallets and 211,000 boxes. Both warehouses, capable of preparing more than 1,000 orders per day in Belgium and 1,500 in France, have a very similar design: they are equipped with pallet racks and shelving with walkways for picking.

About TopTex

Founded in 1994, TopTex is an online textile and fashion accessories shop. The company selects clothes from among some of the best manufacturers, so they can carry the widest variety and best quality fashion. Its product portfolio includes workwear, sportswear, corporate uniforms, etc.

TopTex distributes more than 40 fashion labels, as well as its own brands (Kariban, ProAct, K-Up and Kimood). Moreover, thanks to an international distributor agreement, its products are also sold in countries such as Germany, Austria, Spain, Italy or the United Kingdom, among others.

TopTex in Belgium and France

TopTex had several warehouses in Belgium and France. In this latter country, for example, it had three warehouses on one street, which meant hard-hitting operating costs. It also made it difficult and time-consuming to store and distribute goods to its customers. The company wanted to rework its logistics to accommodate all its products in the same space and process a larger number of orders over the course of each day. At present, it deals with around 44,000 different SKUs in Belgium and 47,500 in France, although it plans to broaden its scope to 50,000 in the coming years.

TopTex has recently built a 23,0002 distribution centre in Villeneuve-lès-Bouloc (France) and, after that, a 10,000 m2 distribution centre in Houdeng-Gœgnies (Belgium). As a result, it brought all its warehouses under one roof together in each country and substantially enhanced its storage space.

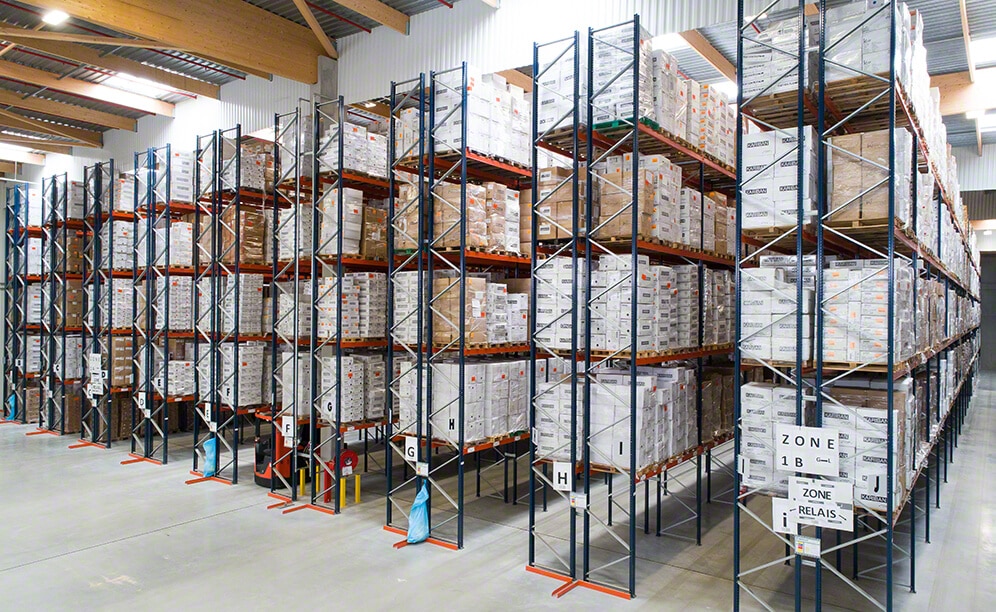

The two warehouses are very similar in their space distribution: the installation of 12 m high pallet racks, as well as shelves with walkways to create a three-story pick structure. It is a design that allows TopTex to reach its desired performance and provide agile, efficient customer care.

Catherine Boisdequin - Managing Director of TopTex Benelux, Germany and Scandinavia

“After conducting a market analysis, we turned to Mecalux to equip our warehouses in France and Belgium because they offered us good value for money. We wanted Mecalux to manage both projects at the same time, so that we could exchange information better.”

Pallet racks

They stand 12 m high and are divided into five levels (maximum), occupying the entire height of the building virtually. “We are pleased with our racks because they use the available space to give us more storage capacity,” explains Vincent Marti, Purchasing and Logistics Manager at TopTex France. The Belgian warehousing facility can store up to 7,136 pallets, while in France (a more substantial building) the figure is 27,390 pallets. The racks are completely adapted to TopTex’s needs, and include rack add-ons to adapt them to the huge variation in the dimensions, volumes and weights of the products. Reserve products for the pick shelves are deposited in these pallet racks.

“Every day we receive a large number of containers and full lorry loads in our French warehouse,” says the Purchasing and Logistics Manager of TopTex France. Once received, the operators are responsible for placing the items on the racks.

Product distribution considers the products’ characteristics and their demand level. Thus, for example, the high rotation ones are deposited in the same zone, on the ends of the aisles to be more exact, to streamline their entry and exit. One of the particular features of these racks is that they give direct access to the products, which speeds up the storage and order fulfilment work. Operators use reach trucks to handle the goods and simply approach the right location for easy pallet insertion and removal.

Pick shelves with walkways

Mecalux has installed 10 m high shelves which have built-in walkways or raised aisleways, creating a total of three storage levels. “We are very satisfied with this solution because it has not only helped us hone our order picking, it has also tripled our storage space,” points out Vincent Marti.

The warehouse has been sectored in order to enhance the installation’s performance. Each one of the levels is set aside for a specific product type and assigned a specific number of operators, which may vary depending on the demand.

Picking is based on the person-to-product criterion, i.e. the operators move through the warehouse and pick the items for each order right off the shelves. More than 1,500 orders end up being prepped in the two warehouses.

The shelves are very versatile and, like the pallet racks, can hold a myriad of distinct SKUs. Both warehouses, in France and Belgium, can store up to 100,000 boxes.

A box conveyor circuit links the three floors and ends up in the consolidation area, where orders coming from different warehouse areas are sorted and prepared. This solution lessens the movements of operators because they do not have to run all over the warehouse. Instead, they select the products that make up each order, only working in the area assigned to them.

Vincent Marti - Purchasing and Logistics Manager of TopTex France

“We decided to work with Mecalux because it is one of the largest companies on the market and because it has a great deal of experience in storage solutions. The racks at our logistics centres stand out for their accessibility, which smooths out the handling of goods and has helped us perform at a level we had always hoped we would.”

Advantages for TopTex

- E-ready warehouses: Toptex's warehouse in Belgium processes up to 1,000 internet purchases daily, while the warehouse in France receives 1,500 orders daily.

- More storage capacity: Mecalux pallet racks exploit the available space while picking shelves with walkways multiply the useful storage area.

- Optimum merchandise distribution: the way the goods are arranged on the shelves or racks means operators can pinpoint each item easily to prep orders and stock storage areas.

| Warehouse in France | |

|---|---|

| System: | Pallet racks |

| Storage capacity: | 27,390 pallets |

| Pallet size: | 800 x 1,200 mm |

| Racking height: | 12 m |

| Racking length: | 90 m |

| System: | Shelving with walkways |

| Storage capacity: | 100,000 boxes |

| Box size: | 600 x 400 mm |

| Racking height: | 10 m |

| No. of levels: | 3 |

Gallery

The shelves are completely adapted to the needs of TopTex

Ask an expert