Cleaning and food products in the new César Iglesias warehouse

César Iglesias has opened a new warehouse in San Pedro de Macorís (Dominican Republic)

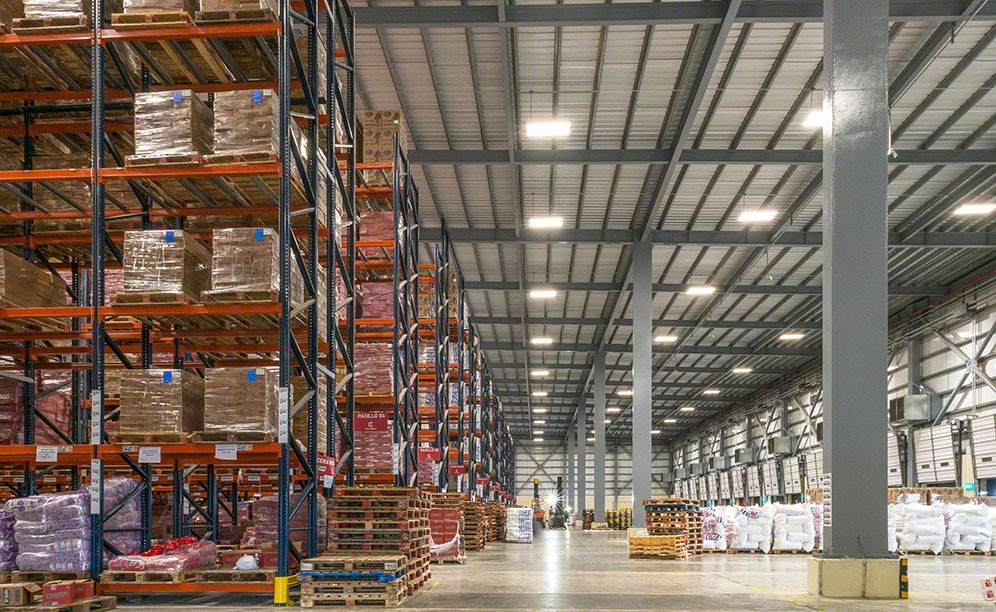

The manufacturer of cleaning and food products César Iglesias has opened a new warehouse in San Pedro de Macorís (Dominican Republic) which has been equipped with Mecalux pallet racks. The company completely overhauled its logistics by allocating this distribution centre to the storage and management of finished products. It can deposit 10,813 pallets in total, ready to be shipped out to customers.

Quality and progress

Active since 1910, César Iglesias is a Dominican company dedicated to the manufacture and marketing of mass consumer products, mainly for cleaning and food ((both hand and dish soaps, laundry detergents and toilet paper, as well as pasta and instant soups, among others).

The company, which employs more than 2,000 people, stands out for its commitment to innovation and for developing new products that improve the lives of Dominicans at an affordable price.

New project, new warehouse

The company has 20 production plants in the town of San Pedro de Macorís and has just recently set up a 12,173 m2 distribution centre there.

Before launching this project, César Iglesias had more warehouses in San Pedro de Macorís, as well as in Santo Domingo, La Vega and Azua. The company has specifically purposed the newly opened distribution centre for the storage of finished products, while the other warehouses are being used to deposit raw material and the materials used in daily production processes.

According to Raúl Abraham, warehouse manager at César Iglesias, “with this project, we wanted to unify all logistics operations in the same warehouse, increase storage capacity to accommodate a large number of products, and have storage systems that would help us to be more efficient.”

With all these ideas in mind, the company contacted Mecalux: “companies in our sector had recently opened new distribution centres and equipped them with Mecalux racks, which motivated us to do the same,” explains Raúl Abraham.

The Mecalux technical team visited César Iglesias’ facilities and, after analysing their needs, made a proposal: to install pallet racks (both single and double-depth), live channels and live picking channels. Incorporating different storage systems in the same space facilitates the management of goods, by organising them based on their characteristics and turnover.

Safety was also a priority for César Iglesias. The Dominican Republic is located in an area of high seismic activity, so all the racks are specifically calculated and reinforced to withstand any possible seismic event that may occur.

The installation of the racks took 90 days, which means that in just three months, the company had a completely new warehouse, adapted to its needs and with enormous potential.

Raúl Abraham - Warehouse Manager of César Iglesias

“We chose Mecalux’s pallet racks because of their quality and because they provide us with great agility in the work of storage and order preparation. Thanks to this warehouse, we can continue to grow and meet the needs of our customers.”

How to optimise operations

400 different SKUs are managed at these facilities, so good warehouse organisation is essential to simplify the work of operators and avoid any possible errors.

The warehouse is divided into different areas to classify each product according to its characteristics. In accordance with this logic, food is stored in the same area, while cleaning products are stored in a different area.

Mecalux’s storage systems also contribute to the proper organisation of the goods, and that is why each type of racking has been assigned to a specific product. For example, double-depth pallet racks have a higher storage capacity compared to single-depth racks, and, by offering direct access, their entries and exits are very fast. With this in mind, they are ideal for articles with a high sales volume and, therefore, rate of movement, such as toilet paper.

The pallet racks are 12 m high and hold 10,397 pallets overall. One of the special features of this storage system is its adaptability to any type of variable load, weight and volume.

Direct access was a priority for César Iglesias because it facilitates storage tasks. Daily, this warehouse receives an average of 1,500 pallets from production and ships another 1,500 to the company’s customers, particularly in the Dominican Republic, the United States and the Antilles.

Picking is also one of the main operations in the distribution centre. For this reason, two solutions designed to achieve higher throughput have been installed: live channels for picking directly from pallets and live channels for picking for orders consisting of boxes.

Actually, they are two similar solutions. These are channels with a slight inclination so that the goods (whether pallets or boxes) enter at the highest point and are moved by gravity and at a controlled speed to the opposite end, where they are ready for removal.

The advantage of these live channels is that orders can be prepared at the same time as the goods are replenished, without interference between the two operations (replenishment takes place in the loading aisle, just across from where picking takes place). In addition, the reserve products remain behind the first pallet or the first box, which prevents service interruptions due to lack of stock.

The customer is the priority

César Iglesias’s objective is to grow with its customers, and it must, therefore, attend to their needs and provide them with the products they want on time. The warehouse plays a major role in this strategy, because it supplies the points of sale with freshly manufactured soaps, pasta and detergents.

Mecalux has helped César Iglesias to overhaul its logistics and make better use of its new warehouse at the same time. The successful organisation of goods and operations is the key element in enabling the entry and exit of 3,000 pallets per day.

Advantages for César Iglesias

- Storage capacity: the pallet racks measure 12 m in height, taking advantage of the entire available surface area to accommodate 10,397 pallets.

- Organisation of goods: each storage system is designed for a specific product. In this way, the 400 SKUs of César Iglesias are under control and possible errors are avoided.

- Quick picking: direct access to goods and live channels for picking help in the preparation of as many orders as possible.

| Warehouse of César Iglesias | |

|---|---|

| Storage capacity: | 10,813 pallets |

| Pallet sizes: | 1,016 x 1,219 mm |

| Max. pallet weight: | 1,100 kg |

| Rack height: | 12 m |

Gallery

César Iglesias cleaning and food products warehouse

Ask an expert