The warehouse for rental dresses from Rent the Runway in the United States

Warehouse with outfits for rent is equipped with multi-level pick modules with walkways and garment hanging

Interlake Mecalux and partner ABCO Systems have supplied a New York-based fashion rental company called Rent the Runway with custom-made pick module systems designed to store the high-end garments in its New Jersey warehouse. With this solution, the company has exponentially improved its storage capacity and, at the same time, increased the productivity of its warehouse workers.

Dream closet in the cloud

Jenn Hyman and Jenny Fleiss founded Rent the Runway in 2009 after realizing it would be smarter for women to rent designer fashion items rather than purchase them. They began their business by setting up a pop-up shop on the campus of Harvard Business School where on-campus students could rent the garments they needed.

Eventually the women decided to launch a website due to the idea’s great success, in which customers could rent clothing online. And, after some positive publicity, they attracted more than 100,000 customers to sign up on their site. Today, the company keeps growing and partners with more than 550 fashion designers to offer women the ‘dream closet in the cloud.’

America’s biggest drycleaner

Rent the Runway’s continued growth necessitated more warehousing space in the town of Secaucus, New Jersey, just outside of New York City. Rent the Runway solicited the help of material handling solutions provider ABCO Systems Inc., an Interlake Mecalux partner, to equip its warehouses with the best solution to store the thousands of articles of clothing that Rent the Runway manages each day.

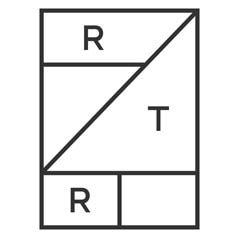

ABCO Systems installed multi-level pick modules featuring Interlake Mecalux racks specifically designed for hanging garments. On each of the three levels, space is available to circulate and facilitate operator handling of the garments. Moreover, strategically placed staircases improve accessibility for the workers on each floor.

The design and chosen solution mean space at heights is fully-used in the building. “This system design revolves around creating flexibility and the ability for Rent the Runway to grow into it as time went by,” explains Seth Weisberg, owner of ABCO Systems. “The focus was on maximising storage space and allowing for all of Rent the Runway’s other processes.”

And this is not the first time Rent the Runway has called upon Interlake Mecalux and ABCO Systems to supply a solution for the company’s logistics needs. ABCO Systems, which has been working with Rent the Runway for more than five years, has built all of the company’s distribution centres and has used Interlake Mecalux products for each project.

A team of more than 200

The pick modules are a flurry of activity on any given day. According to Forbes Magazine, Rent the Runway’s software handles more than 65,000 dresses and 25,000 earrings, bracelets and necklaces destined for any of its 5 million current members. The company’s warehouse in Secaucus employs more than 200 people who handle returns, remove stains from clothing, sterilise jewellery and fix tears.

First, operators scan thousands of bar-coded envelopes into Rent the Runway’s computer system, which decides what items will ship to a customer or which ones can remain in the warehouse.

Operators then inspect the dresses and sort them one by one into bins designated for regular cleaning, stain removal or repairs.

After that, workers remove stains from clothing by consulting a database that recommends the best chemicals to use for each stain. The warehouse also has automated steam cleaning machines used to instantaneously sterilise and smooth gowns. Lastly, workers are responsible for repairing any tears to clothing and reattaching beads and sequins.

Once these processes are finished, operators assemble, check, bag and distribute orders. The Forbes article mentions how the company’s computer management system predicts dress demand and selects the most cost-effective shipping method for returns.

Much of this work occurs in the Interlake Mecalux pick modules. ABCO Systems and Interlake Mecalux worked with the operations team of Rent the Runway to determine the best layout for the system based on Rent the Runway’s specific storage and distribution requirements.

Seth Weisberg - Owner of ABCO Systems Inc.

“As Rent the Runway continues to grow, ABCO Systems and Interlake Mecalux continue to support them.”

Advantages for Rent the Runway

- Space optimisation: racking with walkways maximises the storage space and has doubled the number of products Rent the Runway can house.

- Enhanced safety: the design of the pick modules ensures the safety and productivity of Rent the Runway’s workers.

- Greater flexibility: Rent the Runway’s warehousing system has the ability to adapt to the company’s needs in the future.

Gallery

Three-storey rack modules with walkways at Rent the Runway

Ask an expert