Molendum Ingredients (Dacsa Group) transforms logistics processes for natural flour

The producer of natural legume- and grain-based flour deploys Easy WMS to manage inventory and connect the warehouse with the production lines.

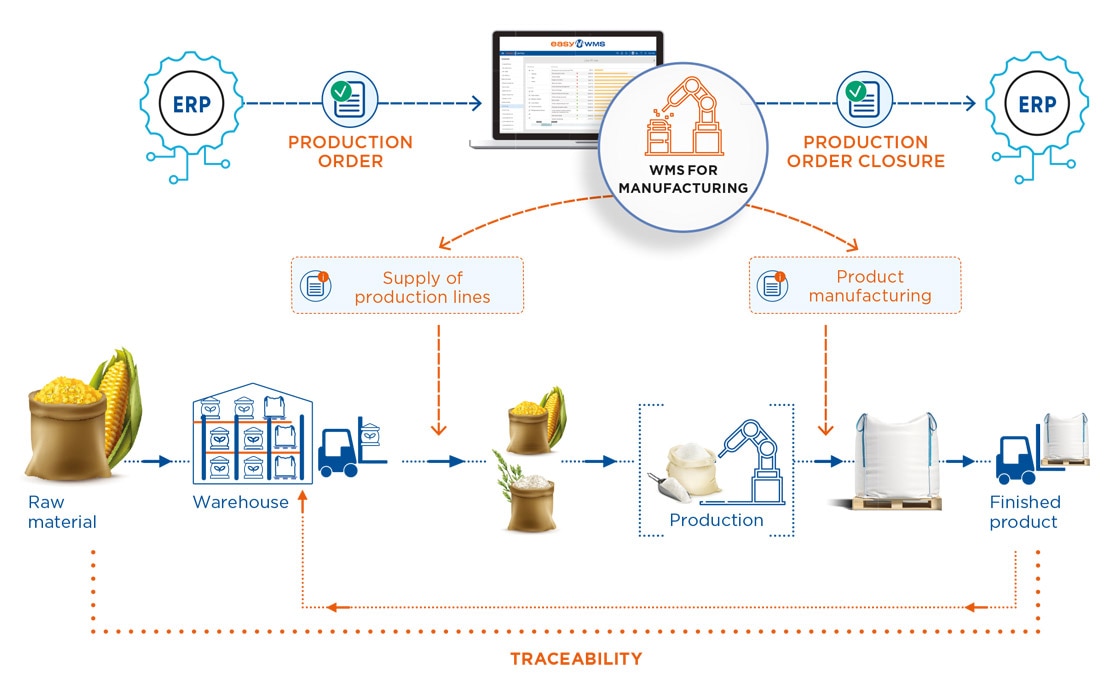

Molendum Ingredients, a producer of natural legume and cereal flour, has implemented Mecalux’s Easy WMS warehouse management system in its facility. The software ensures full traceability of raw materials, from their arrival at the plant to their transformation into the final product.

Molendum Ingredients: Redefining the food industry’s future with functional ingredients

Molendum Ingredients manufactures 100% natural flours made from legumes and grains. Its allergen-free products are produced exclusively through mechanical processes, without any chemical treatments. The company is part of Dacsa, a leading European industrial group known for its corn-based food products and as one of the largest rice producers on the Iberian Peninsula.

Founded in 2014, Molendum Ingredients has a team of over 60, distributes to more than 11 countries and specialises in milling legumes and ancient grains. It operates Spain’s first extrusion-processed heat-treated flour plant and the country’s first wet-textured protein factory.

CHALLENGES

|

SOLUTIONS

|

BENEFITS

|

|---|

Food solutions manufacturer Molendum Ingredients, a Dacsa Group company, has embraced technological innovation by implementing Mecalux’s Easy WMS warehouse management system in its facility in Coreses (Zamora).

This software has boosted the business’s logistics processes, reinforcing its commitment to quality and sustainability. “Molendum is experiencing significant growth and we have a clear vision for continuous expansion. To keep pace, we needed to optimise our operations,” says Raúl Aparicio, Project Manager for the WMS implementation at Molendum Ingredients.

The company turned to Mecalux to upgrade its inventory management capabilities. “Previously, everything was tracked manually, with logistics staff recording inventory in an Excel sheet. But this method was prone to errors and didn’t provide real-time data. When stocktaking, we’d find major discrepancies between what was written down and the actual inventory levels,” says Aparicio.

Located next to the production lines, Molendum Ingredients’ warehouse stands out for its complexity. Spanning 3,000 m², it handles over 300 SKUs, including unmodified and heat-treated flours, breadcrumbs and textured proteins. These ingredients are used across the food industry, especially in ready meals, meat products and snacks.

“We work with a wide range of raw materials — some in small batches but with high economic value. So it was crucial to maintain effective control over quantities and costs. Easy WMS allows us to manage our inventory much more accurately,” says Aparicio.

Strategic organisation of goods

With Easy WMS, Molendum Ingredients maintains real-time product traceability. Warehouse operators can easily check the exact location of each SKU on their RF scanners, streamlining processes and reducing the risk of errors.

The Mecalux software distributes inventory with a functional approach. Finished products are placed near the loading docks to speed up order fulfilment and shipment. In contrast, raw materials and packaging are stored close to the milling and packing areas to ensure swift supply to the various process lines. “The strategic inventory layout is designed to optimise internal flows and reduce operator travel,” says Aparicio.

Warehouse connected to production

Molendum Ingredients’ logistics operations are fully integrated with its milling processes. The company has implemented WMS for Manufacturing, an Easy WMS module that oversees the flow of raw materials to production.

With this application, operators receive instructions on their RF scanners indicating which materials to send to the production lines, how many and when. Aparicio says: “As tasks are carried out, the actual consumption of each ingredient or packaging material is recorded in real time.”

The software also integrates pallets holding finished goods into the system, assigning them a storage location as they are created. “With Easy WMS, we track each raw material throughout its entire journey: from its arrival at the warehouse to its conversion into a finished product,” says Aparicio.

Customised labels for clients

Molendum Ingredients has also implemented Client-Specific Rules to adapt logistics processes to individual customer requirements. With this Easy WMS functionality, the company can configure custom actions, such as generating personalised labels for each client.

“Some companies request a particular label format. With Client-Specific Rules, we can automatically generate a customised label instead of printing the standard one,” says Aparicio. This automation speeds up operations, boosts productivity and improves service reliability.

Scalable logistics for future growth

Molendum Ingredients has modernised its warehouse to increase operational efficiency, ensure product traceability and respond to market demands. By automating processes such as production supply and label customisation, the company has optimised its resources while maintaining flexibility.

“When we started our supply chain digitalisation project, we had estimated a certain number of inbound and outbound operations. By the time Easy WMS was implemented, that number had already increased significantly. Fortunately, the system is designed to scale with us and support our growth,” says Aparicio. Now, the flour manufacturer can take on a larger workload and meet new challenges confidently, with its eyes set on the future.

With Easy WMS, we track each raw material throughout its entire journey: from its arrival at the warehouse to its conversion into a finished product.

Gallery

Molendum Ingredients (Dacsa Group) equips its warehouse with Mecalux’s Easy WMS

Ask an expert