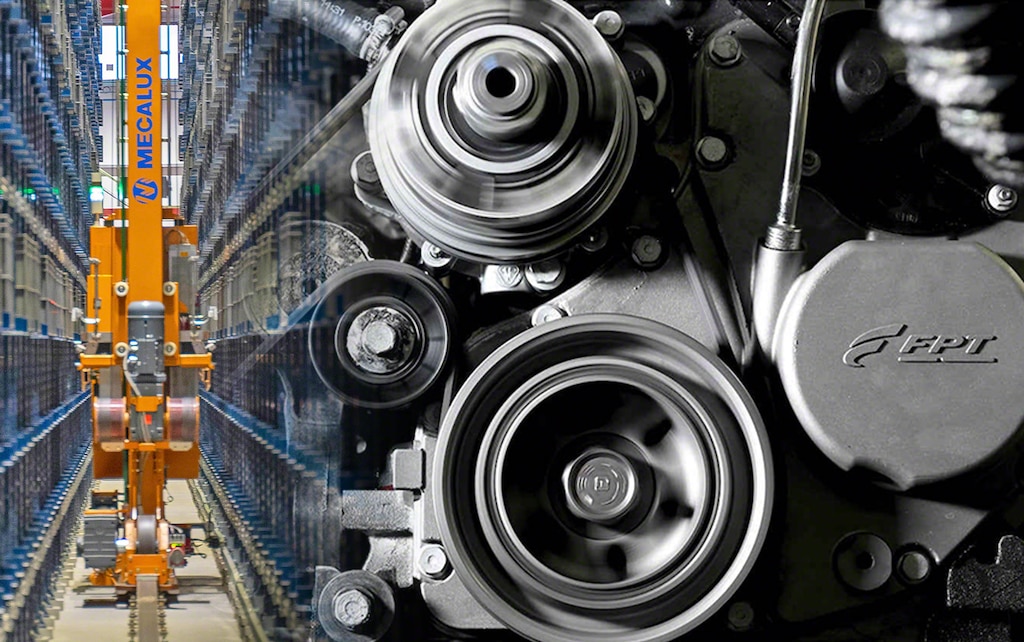

FPT Industrial, a manufacturer of engines and transmissions for industrial vehicles, has set out to boost its business and strengthen its growth prospects for the coming years. To achieve this goal, it is expanding its logistics facility in Bourbon-Lancy, France. There, Mecalux will instal an additional aisle in the company’s automated warehouse for boxes, thereby doubling its storage capacity and flows.

Initially, FPT’s automated installation for boxes comprised a single aisle with double-deep racking on both sides and a storage capacity of 7,272 boxes. The new aisle will raise the capacity to 15,120 boxes that will house small parts used to supply the engine production lines.

All operations will be fully automated. In each aisle, a miniload stacker crane will insert and remove boxes into/from their locations as per instructions from Mecalux’s Easy WMS warehouse management system. This powerful software will assign a slot to each product based on its characteristics and turnover.

In total, the installation will consist of two aisles with miniload stacker cranes, two pick stations (where orders will be prepared according to the product-to-person criterion), and a goods receipt station.

After seeing how effective the first stacker crane was and how well it worked, we decided to instal a second miniload system as the next step to automating our logistics processes. This expansion will enable us to meet the productivity objectives we’ve set and will serve as the basis to continue automating the flows that go from the warehouse to the production lines. And all of this is carried out with product-to-person operations.

About FPT Industrial

FPT Industrial designs, develops, manufactures and sells powertrains for industrial vehicles. With over a century of experience, the company is a trailblazer in its sector, introducing technological innovations that enhance performance and reduce emissions. Its centre in Bourbon-Lancy is renowned for its operational excellence, thanks to the high-level technical qualifications of its workers and its top-grade service quality.